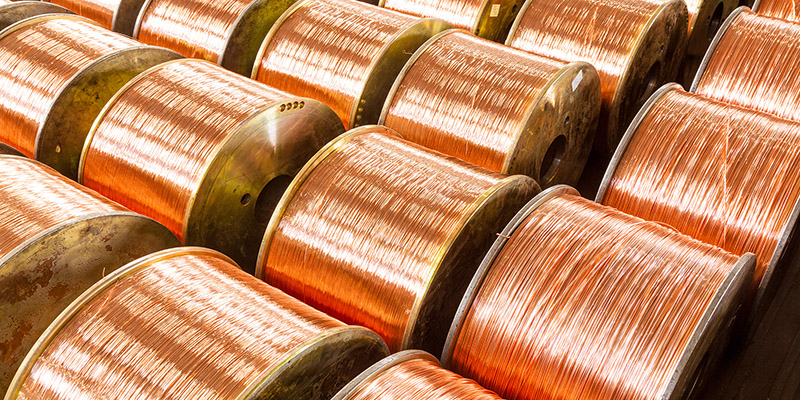

An Introduction To Copper Wires And Upcoming Trends Related To Them

Posted on Jul 31, 2018

Copper enjoys preferential treatment when it comes to electric wiring. When telephone was invented, demand of copper wires further increased. Copper plays a crucial role of ‘electric conductor’ in various categories related to electrical wiring.

Prominent use of copper wires

Copper wire is used in power generation to transmission and distribution.

It is used in electronic circuitry

It is used in extensive range of electrical equipment’s

Copper and its diverse alloys are employed in fabrication of various electrical contacts

It is used in manufacturing of electrical wire

It is used in manufacturing of cable conductors

Copper: A preferred metal for electric wiring purpose

Various distinguished properties of copper make it an utmost ideal component to fabricate wire, meant for electric wiring purpose. Let us have a glance on those properties:

Superior electrical conductivity: Long mean free path of copper imparts it with superior electrical conductivity. In simple words, copper wire really performs well while transporting electric charge.

Superior tensile strength: Due to featuring higher degree of tensile strength, copper wire naturally poses itself as an ideal component to be used in building industry. Due to such tensile strength, it becomes possible for a copper wire to be anti-resistant against creeping, etc and thereby to prevent interruptions in service.

Higher ductility: Since copper features higher ductility, it becomes possible for it to undergo intense hammering, rolling, drawing, etc. Tolerance of a wire really plays a crucial role in ensuring that while a wire undergo several intense stages, it does not break or crack.

Incredible flexibility: Copper wire can effortlessly undergo bending, twisting, pulling that too without showing any signs of stretching or breakage. Its anti-corrosion properties certainly increase its appeal.

Upcoming trends related to copper wire and cable

Bare Copper Cable is expected to continue ruling the roost in upcoming future as well in context of electrical wire applications. We all know that automotive segment do give preference to those wires that feature small diameter. In specific applications of automotive industry, small diameter wires are required. It is gradually becoming a common practice among manufacturers to employ alloys like copper-magnesium.

Use of such alloys facilitates small diameter wires not merely to attain lightweight but their conductivity performance also enhance up to a large extent. Thus, in forthcoming time, we should not be surprised if copper magnesium alloy witness tremendous increase in demand in the context of range of applications related to aerospace, defense and automotive segment.

In coming future, requirement related to broadcasting of high-speed data and high speed voice, will increase. Due to the same reason, demand related to superior durability along with movement towards ‘zero defects’ in conductors featuring copper, will continue to increase.

As far as non-cryogenic temperature is concerned, 4-nines copper is expected to be dominating material for majority of wire applications, meant for commercial purposes. However, production of 6-nines copper wire in little quantities has already taken place, but due to being extremely expensive, it is not going to witness popularity. Moreover, its use is avoidable in few key domains like telecommunications, building wire, etc. Thus, it is unlikely to replace 4-nines copper wire.