Copper Wires- An Insight Into Application Areas Benefits

Posted on Jul 18, 2018

Copper is an extremely useful metal and it enjoys a preferential treatment due to being a good electrical conductor. The symbol of this ductile metal is Cu and the atomic number possessed by it accounts for 29. Wires made of copper metal are used extensively in various key manufacturing industries.

Applications of Copper wires:

-> Copper is a good conductor of electricity and heat. This property makes Copper Wires extremely ideal for numerous applications. Below are few of the major application areas of the wires made up of copper.

-> Copper wires are used extensively in construction industries.

-> They are used widely in electrical industries.

-> They are used in various projects related to the power including power generation, transmission and distribution.

-> They are used in the domain of telecommunications.

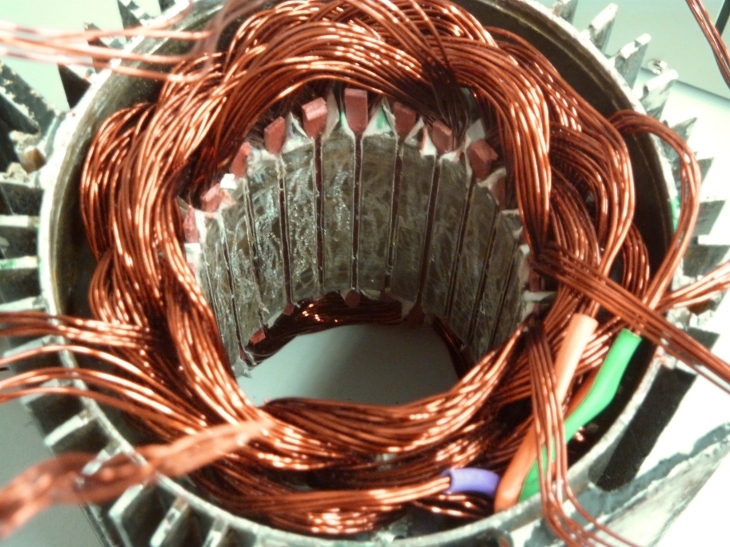

-> They are used in electronics circuits and numerous electrical equipments.

Why copper wires are used extensively?

Superior Electrical Conductivity: In comparison to the majority of the non-precious metals, copper proves to be a wonderful conductor of electricity. Insulated Copper Wires made up of copper are competent of allowing more electrical current/ diameter of wire. In simple words, a wire of copper drains less charge during the time when electricity passes through it.

Flexibility: This is one of the major attractive facets of copper. It is possible to stretch the copper without letting it weaken or break. Due to the same reason, this metal proves to be extremely useful in manufacturing wires.

Corrosion-Free: Copper possesses some exclusive chemical properties due to which it is resistant to the rust. Copper can withstand adverse climates and it doesn’t wear with a fast pace. Due to being rust-resistant, it proves to be an ideal metal for manufacturing wires.

Universal Standard: Wires made up by using copper are accepted globally. Be it domestic purpose, or be it commercial purpose, copper wiring is used extensively across the entire globe. It also becomes easier to rewire in the future, due to using copper wiring.

Hassle-Free Availability: Since, copper wires are available almost everywhere on local electrical stores; it becomes easier to use them, whenever required. The major popular varieties of copper wires include tinsel copper wire, a wire featuring tin coating, braided copper wire, etc. It is also easier to choose from an extensive variety of sizes of all these types of wires.

Copper Winding Cables are good for transferring the current. When a high voltage of current passes through a wire, the surface temperature of it is expected to increases. Considering the rapid fall and rise of the temperature in a wire, it becomes imperative for a wire to remain unchanged. For the same purpose, copper wire appears absolutely ideal as it possesses a capability of sustaining the frequent and intense fluctuations in the temperature.

To put it in a nutshell, almost all electrical devices are dependent on the copper wiring due to the dynamism possessed by it. Apart from the above mentioned properties, copper is preferred for manufacturing wires due to being equipped with tensile strength, low thermal expansion and ease of installation.